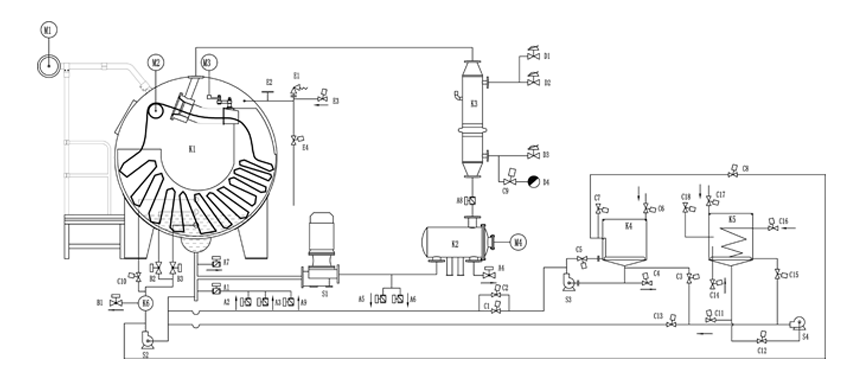

K1=Main Kier K2= Filter K3= Heat Exchanger K4=Dosing Tank 1

K5=Dosing Tank 2 K6=Filter S1=main pump S2 = Master cylinder circulating pump

S3= Barrel 1 feed pump S4= Barrel 2 feed pump

GIANT Plus is designed for pretreatment, dyeing & after treatment of woven, knits and nonwovens in both synthetic fibers and natural fibers.

GIANT Plus is capable to handle crease, surface, color sensitive fabric, thanks to high efficiency even-flow circulation system combined MHL low tension lifting system, GIANT Plus can output excellent average dyeing result even under 500kgs/Tube load capacity, no tube and sectional difference appears on the fabric. simultaneously perfect fabric surface are also obtained successfully!

1- Extra low liquor ratio ,1:3-4 for normal active dyeing, water consumption is between 20-40L per kg fabric (from light to dark color).

2- MIP multi-inlet pump and “Even-flow” system ensures the dyeing liquor can be mixed average before each injection to the nozzle, circulation efficient are increased 300%.

3- “Even-flow” dosing system can ensue no tube and section difference.

4- MLH Low tension design ensures fabric are processed under minimum tension, thus reducing the crease marks, wearing, and proper dyeing to edges under open width process.

5- Typical processing time can be 4.5-5hours.

Liquor ratio: 1:3-4

Max. Lifting speed: 500M/min.

Designer temperature:140℃

Designed pressure :3.5Mbar

Heating gradient:5℃/min.from25℃-100℃

Cooling gradient:2℃/min.from100℃-85℃